As Europe intensifies its digital infrastructure efforts, fiber optic networks have become the cornerstone of sustainable connectivity. While performance benchmarks often dominate industry dialogue, the underlying physical infrastructure — especially microduct systems — plays a critical role in shaping long-term deployment efficiency and resilience.

Effective microduct design impacts not only the cost and speed of fiber rollout but also future-proofing strategies, environmental performance, and urban compatibility. Engineering decisions made at the planning stage can either accelerate network expansion or introduce limitations that are costly to reverse later.

Balancing Urban Constraints with Long-Term Flexibility

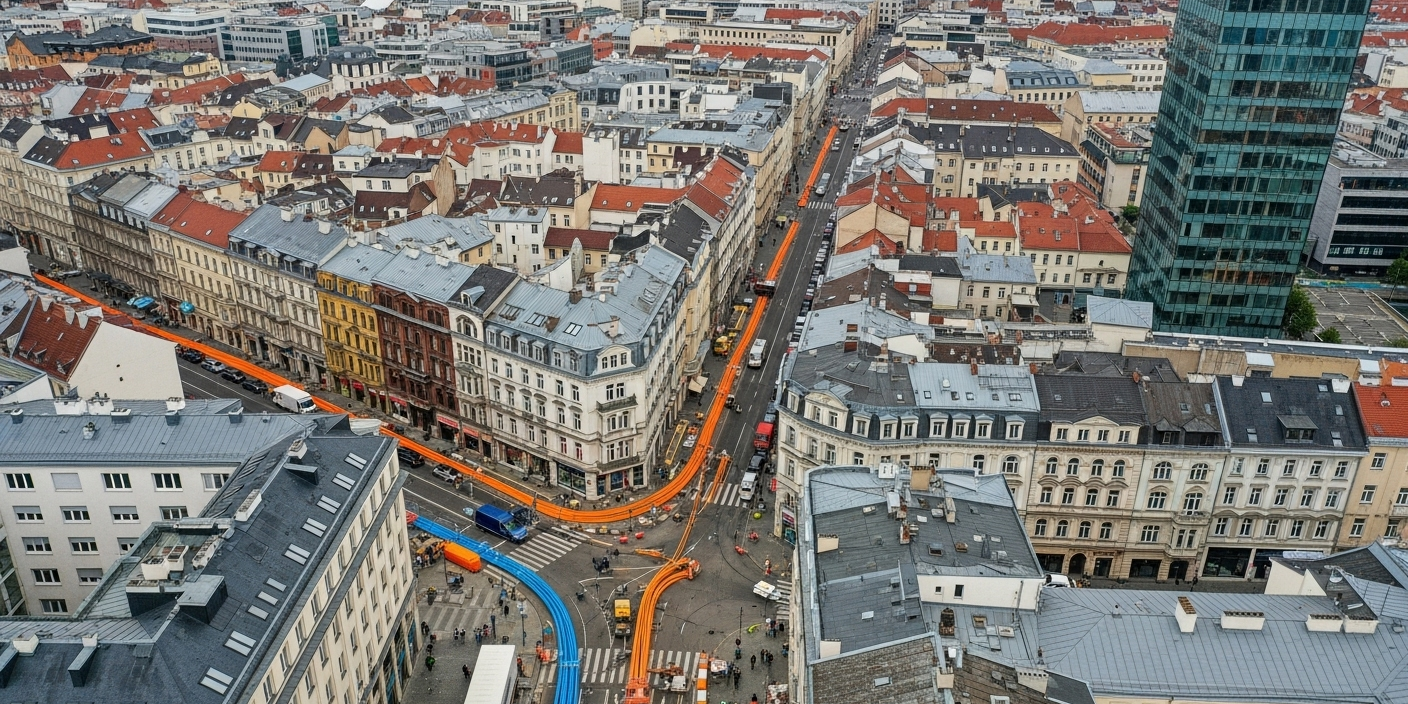

Urban areas present specific challenges such as limited trench space, road crossing restrictions, and high installation costs. These challenges call for solutions that balance physical constraints with capacity expansion over time.

Modular and bundled microduct designs help operators address space limitations while preserving future scalability. In multi-dwelling units (MDUs) and smart buildings, vertical installations require lightweight and fire-safe materials, like LSZH-compliant ducts, to meet strict building codes.

Sustainability in Underground Infrastructure

Sustainability now extends beyond data center power usage to the materials and methods used in infrastructure. The selection of raw materials, reusability of ducts, and minimized excavation through micro-trenching all influence a network’s environmental footprint.

Recyclable polymers, reduced energy use during manufacturing, and resistance to aging and mechanical stress all contribute to a lower long-term carbon impact. Operators are increasingly seeking suppliers who can demonstrate certified environmental compliance in their materials and processes.

Lessons from the Field: What Scalable Designs Share

Across Europe, the Middle East, and North Africa, field-tested microduct deployments share several characteristics:

-

Bundled duct configurations reduce the need for future civil works.

-

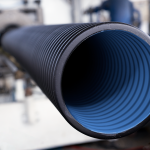

Ribbed or silicon-lined inner surfaces enhance cable blowing performance.

-

Color coding and striping improve installation accuracy and maintenance speed.

-

Duct systems undergo rigorous pressure, impact, and crush resistance tests to verify performance in extreme conditions.

Applied Innovation: A Case from Industry

One example of these design principles in action can be seen in modular microduct systems developed by Esen Plastik. Unlike conventional ducting, Esen’s solutions feature customizable bundled configurations, low-friction inner surfaces for enhanced cable jetting, and certified LSZH materials — making them particularly well-suited for complex deployments where speed, safety, and future scalability are critical.

These features reflect not just manufacturing quality but a deep alignment with the evolving needs of fiber operators across multiple geographies.

Reframing Infrastructure as Strategic Enabler

As the industry races toward higher bandwidth and denser networks, duct systems must be seen not just as conduits but as long-term strategic assets. When properly designed, they support incremental upgrades, reduce environmental impact, and lower total cost of ownership over time.

By prioritizing scalability and sustainability in microduct planning, network builders can ensure that fiber infrastructure serves not only today’s demand — but tomorrow’s opportunities.