Infrastructure system need has started to take its place in history by the process of urbanization and settled life of people with agriculture. After this need, human beings have taken their first steps to remove rainwater, wastewater, and sewage water through open channels and clay pipes. In the process that continues until today, different pipe types and methods have been developed, as a result of these developments building systems have been created.

Developing and growing urban populations from the past to the present time, infrastructural needs increased exponentially and this continues now. With this situation, governments have been started to give more importance and have started to develop infrastructure projects that can serve for many years rather than meeting their daily needs in infrastructure investments.

It has been understood that the world should be meticulously emphasized infrastructure investments, especially sewage and wastewater infrastructures.

Polluted water from households and businesses was delivered to treatment facilities without loss to the nature and this should be one of the most important issues for public health and environmental cleaning. For this reason, the selection of pipes to be used in the preparation phase is the most important point of sewerage, wastewater, rainwater infrastructure projects.

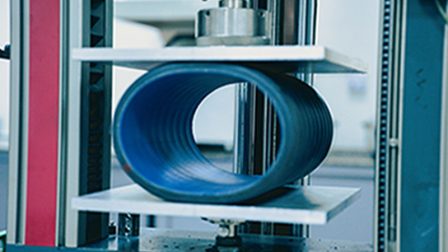

The strength of the pipe to be used in infrastructure projects, construction, and maintenance as well as its features such as tightness, operational life should also be considered.

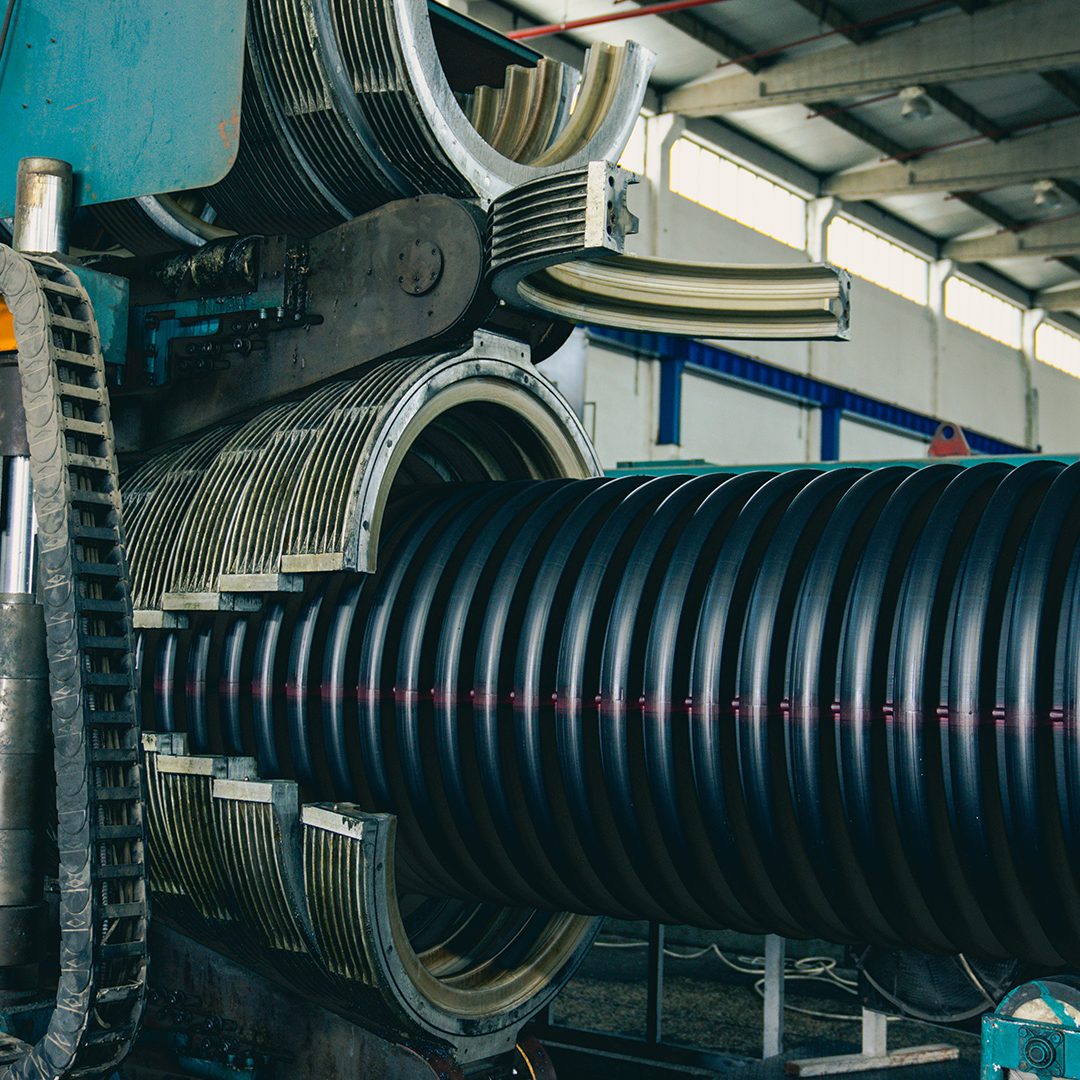

ESEN HDPE Corrugated Pipes and Fittings have high flow performance, external load resistance, such as long working life, chemical resistance, easy maintenance, tightness besides many other features; has been serving with high quality understanding for many years.