The pipes are produced within the scope of our company’s production activities; desired quality requirements,quality plans, standards, customer specifications checking their conformity and quality continuity to ensure every stage of production is taken under control .

Polyethylene 100 (PE100) | is the strongest PE pipe material is known today

HDPE pipes produced with PE 100 raw material are resistant to high pressure compared to Traditional PE pipes produced with its raw materials. The water pressure of 16 bar has reached 32 bar in pipes which are produced with upper limit PE100 raw material. Thus, it has started to replace traditional pipes (steel, cast iron, ductile…) in the water transfer main pipes.

PE100 pipes are coiled up to 125 mm diameter or on request 6, 12, and 13.5 mt as straight pipes; Over 125mm diameters are produced only in straight pipes of 6, 12, and 13.5 mt. Also depending on customer demand production can be made in special sizes.

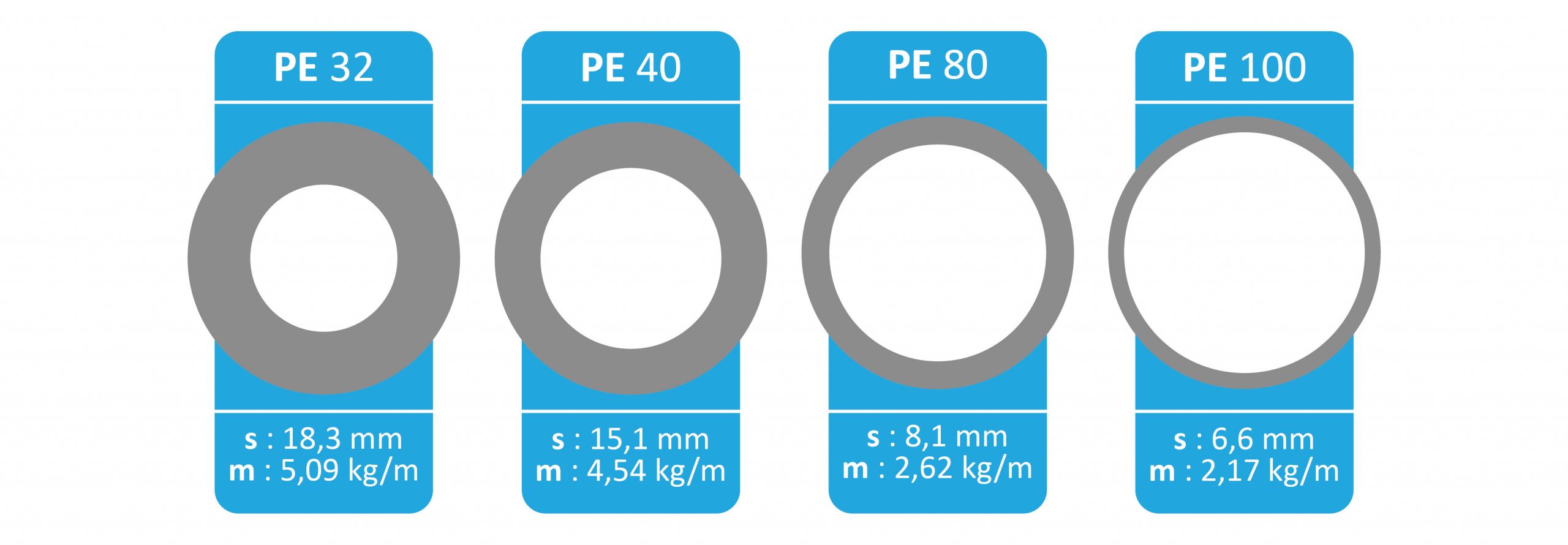

With an outer diameter of 110 mm and a working pressure of 10 bar for a pipe PE 32, PE 63, if they are produced from PE100 raw materials, wall thicknesses and their weight will be according to the given data on the above. >

s : Wall Thickness, m: Meter Weight

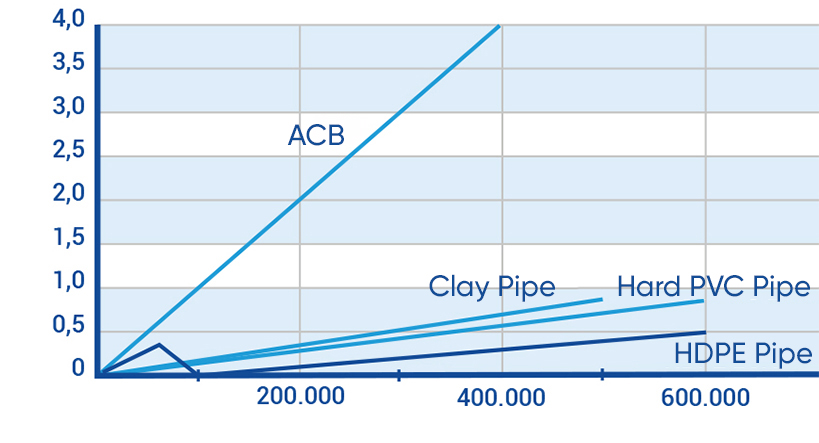

Comparison of ESEN PE100 (HDPE) Pipes with Other Pipes

Other pipes STEEL, DUCTILE, CONCRETE Pipes ;

-

While the life service of other pipes is 5-10 years; ESEN PE100 (HDPE) designed Pipe life service is 50 years.

-

Other pipes are exposed to corrosion due to their structure, due to the effect of decay, in process of time the wall thickness of the pipe decreases and over time causes the pipe to break or perforate; ESEN PE100 (HDPE) Pipes are not corroded.

- Other pipes break in ground movements (earthquakes, landslides, etc.) and/or separated from the connection points. However ESEN PE100 (HDPE) Pipes due to their molecular structure, they are not affected by ground movements (earthquake, landslide, etc.) with their ability to extend over 500%, they are not separated from the connection points. Continuing to serve after natural disasters caused by ground movements (earthquake, landslide etc.)

- ESEN PE100 (HDPE) Pipes have higher impact strength than other pipes.

- ESEN PE100 (HDPE) Pipes have a lower friction coefficient than ductile, steel, etc. pipes. For this reason, it provides the opportunity to use a lower diameter pipe in pressurized drinking water lines and allows the selection of a lower energy pump, thus it provides savings on initial investment and operating costs.

-

It allows transportation costs to be reduced due to its lighter weight than other pipes.

- ESEN PE100 (HDPE) Pipes (up to 125mm) can be produced as coils; It allows to make less assembly points than other pipes.

- ESEN PE100 (HDPE) Pipes are preferred in projects instead of other pipes; provides savings on material cost, transportation, assembly, labor, etc. costs. Projects can be implemented with less cost.

The photo of the corroded ductile pipe after 5 years.

The photo of the corroded ductile pipe 20 years later.

ESEN PE100 (HDPE) | Advantages of the Pipe

-

Since its density is 0.950 gr / cm3, it is 8 times lighter than steel.

- It is easy to carry and it does not deform.

- Due to the fluid passing through it and the soil structure outside, it does not corrode.

- It has a high resistance to chemicals.

- On the clean water lines, PE pipe does not have a carcinogenic effect since it does not mix foreign particles/substances.

- It is suitable for health as it does not change the smell, taste, and color of the water.

- As it is included in the thermoplastic product group, it is an environmentally recyclable product.

-

Thanks to its elastic structure, it provides 500% elongation; in the event of earthquake and landslide, it extends and absorbs opening; breakage, rupture does not occur.

-

As it has been produced with carbon black additive, It shows resistance to ultraviolet rays from the sun.

-

Maintains its elastic feature even when the temperature drops to -40 °C, it expands, it is not affected by the volume increase.

-

It adapts even if the ground is not gradually excavated.

-

Assembling operation can be made outside the channel and applied to the channel.

- Since it is assembled with Butt Welding or EF Welding System; the composed line becomes solid and foreign materials such as groundwater, plant, and tree roots cannot enter the pipeline.

-

It does not create wastage in assembly due to its joining methods.

- It can be produced as coils up to 125 mm in diameter. Coil production; fitting and they save on welding cost and reduce the risk of welding workmanship errors.

- Adapts to the shape of the land during laying, it saves costs in its excavation and channel work.

- It provides ease in river, lake, and sea crossings, and it reduces project costs a lot.

-

It can be produced with different pressures in accordance with the project; It is effective in saving raw materials and cost-effective projects.

-

It meets the same compressive strength with a thinner wall thickness compared to conventional PE pipes.

ESEN PE100 (HDPE) | Usage Areas

-

Drinking Water, Potable Water Systems

-

Agricultural Irrigation Water Systems

-

Waste Water, Sewerage Discharge and Treatment System

-

Marine Discharge Systems

-

River, Lake, Submarine Pass Systems

-

Chemical / Abrasive Transfer Systems

-

Methane Gas Evacuation Systems

-

Fish Farms and Marinas

-

Fire Installation main lines

-

Drainage Systems

-

Geothermal Pipe Cover Systems

-

Telecommunications Group

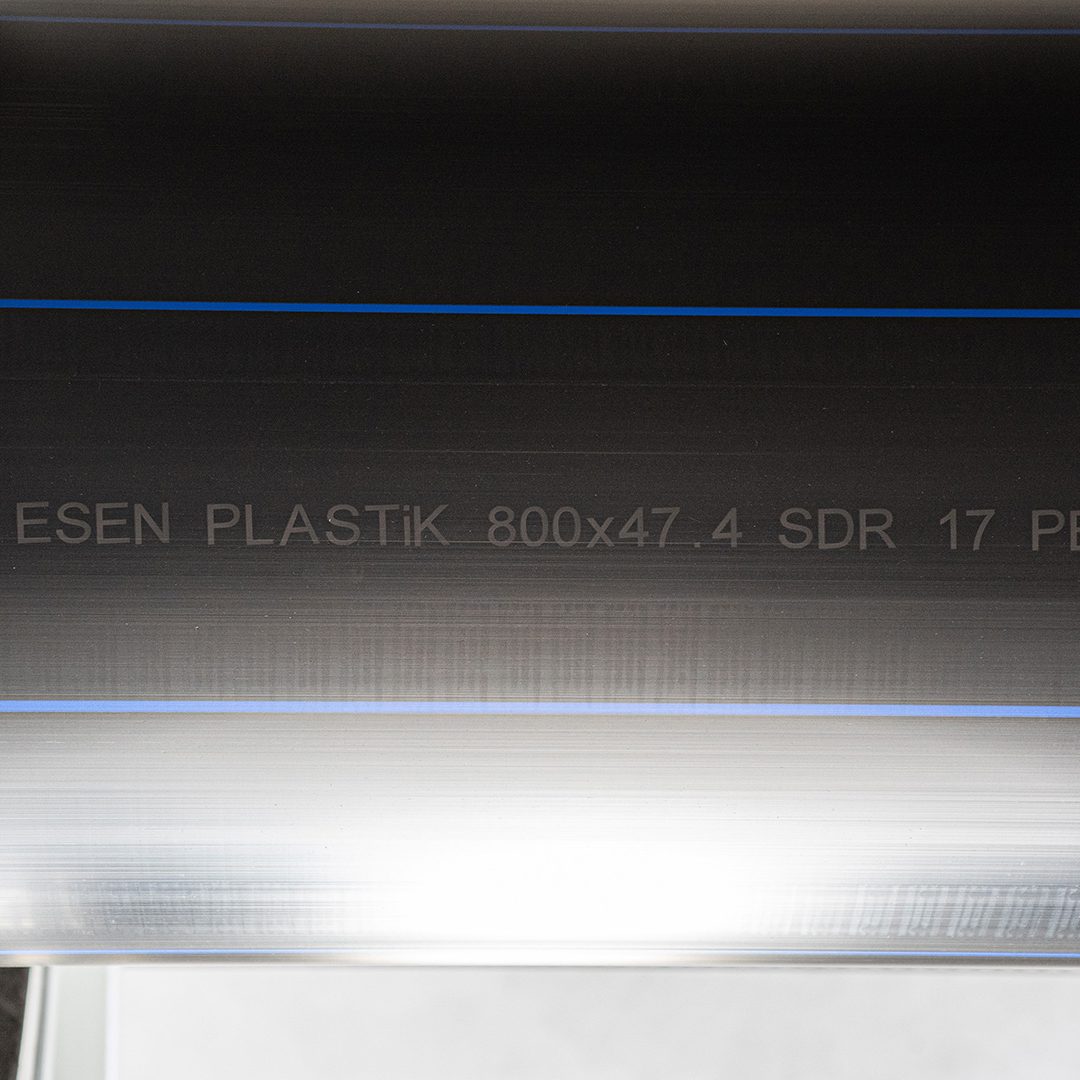

ESEN PE100 (HDPE) | Pipe Diameter and Dimensions

| Outer Diameter (DN) |

SDR 41 PN4 |

SDR 33 PN5 |

SDR 26 PN6 |

SDR 21 PN8 |

SDR 17 PN10 |

SDR 13.6 PN12.5 |

SDR 11 PN16 |

SDR 9 PN20 |

SDR 7.4 PN25 |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S/mm | Kg/m | S/mm | Kg/m | S/mm | Kg/m | S/mm | Kg/m | S/mm | Kg/m | S/mm | Kg/m | S/mm | Kg/m | S/mm | Kg/m | S/mm | Kg/m | |

| 20 | – | – | – | – | – | – | – | – | – | – | – | – | 2 | 0.112 | 2.30 | 0.133 | 3 | 0.154 |

| 25 | – | – | – | – | – | – | – | – | – | – | 2 | 0.152 | 2.30 | 0.171 | 3 | 0.22 | 3.5 | 0.24 |

| 32 | – | – | – | – | – | – | – | – | 2 | 0.187 | 2.4 | 0.232 | 3 | 0.272 | 3.6 | 0.327 | 4.40 | 0.386 |

| 40 | – | – | – | – | – | – | 2 | 0.239 | 2.4 | 0.295 | 3 | 0.356 | 3.7 | 0.43 | 4.5 | 0.509 | 5.5 | 0.6 |

| 50 | – | – | – | – | 2 | 0.314 | 2.4 | 0.359 | 3 | 0.453 | 3.7 | 0.550 | 4.60 | 0.666 | 5.6 | 0.788 | 6.9 | 0.936 |

| 63 | – | – | – | – | 2.5 | 0.494 | 3 | 0.565 | 3.8 | 0.720 | 4.7 | 0.873 | 5.8 | 1.05 | 7.1 | 1.26 | 8.6 | 1.47 |

| 75 | – | – | – | – | 2.9 | 0.675 | 3.6 | 0.80 | 4.5 | 1.02 | 5.6 | 1.24 | 6.8 | 1.47 | 8.4 | 1.76 | 10.3 | 2.09 |

| 90 | – | – | – | – | 3.5 | 0.978 | 4.3 | 1.160 | 5.4 | 1.46 | 6.7 | 1.77 | 8.200 | 2.12 | 10.1 | 2.54 | 12.3 | 3 |

| 110 | – | – | – | – | 4.2 | 1.43 | 5.3 | 1.74 | 6.6 | 2.17 | 8.1 | 2.62 | 10 | 3.14 | 12.3 | 3.78 | 15.1 | 4.49 |

| 125 | – | – | – | – | 4.8 | 1.84 | 6 | 2.200 | 7.4 | 2.76 | 9.200 | 3.37 | 11.4 | 4.08 | 14 | 4.87 | 17.100 | 5.77 |

| 140 | – | – | – | – | 5.4 | 2.320 | 6.7 | 2.8 | 8.300 | 3.46 | 10.3 | 4.22 | 12.7 | 5.08 | 15.7 | 6.11 | 19.2 | 7.25 |

| 160 | – | – | – | – | 6.2 | 3.04 | 7.7 | 3.68 | 9.5 | 4.520 | 11.8 | 5.5 | 14.6 | 6.67 | 17.900 | 7.96 | 21.9 | 9.44 |

| 180 | – | – | – | – | 6.9 | 3.79 | 8.6 | 4.63 | 10.7 | 5.71 | 13.3 | 6.98 | 16.400 | 8.42 | 20.100 | 10.1 | 24.6 | 11.9 |

| 200 | – | – | – | – | 7.7 | 4.70 | 9.6 | 5.73 | 11.9 | 7.05 | 14.7 | 8.56 | 18.2 | 10.4 | 22.4 | 12.4 | 27.4 | 14.8 |

| 225 | – | – | – | – | 8.6 | 5.89 | 10.8 | 7.26 | 13.4 | 8.93 | 16.600 | 10.9 | 20.5 | 13.1 | 25.2 | 15.8 | 30.8 | 18.6 |

| 250 | – | – | – | – | 9.6 | 7.3 | 11.9 | 8.9 | 14.8 | 11 | 18.400 | 13.4 | 22.7 | 16.2 | 27.9 | 19.4 | 34.200 | 23 |

| 280 | – | – | – | – | 10.7 | 9.1 | 13.4 | 11.22 | 16.600 | 13.7 | 20.6 | 16.8 | 25.4 | 20.3 | 31.3 | 24.3 | 38.300 | 28.9 |

| 315 | 7.7 | 7.52 | 9.7 | 9.37 | 12.1 | 11.6 | 15 | 14.13 | 18.7 | 17.400 | 23.2 | 21.2 | 28.6 | 25.6 | 35.200 | 30.8 | 43.1 | 36.5 |

| 355 | 8.7 | 9.55 | 10.9 | 11.8 | 13.6 | 14.6 | 16.900 | 17.940 | 21.1 | 22.1 | 26.1 | 26.9 | 32.200 | 32.5 | 39.700 | 39.1 | 48.5 | 46.3 |

| 400 | 9.8 | 12.1 | 12.3 | 15.1 | 15.3 | 18.6 | 19.100 | 22.84 | 23.7 | 28 | 29.4 | 34.1 | 36.300 | 41.3 | 44.7 | 49.6 | 54.7 | 58.8 |

| 450 | 11 | 15.3 | 13.8 | 19 | 17.2 | 23.5 | 21.5 | 28.9 | 26.7 | 35.4 | 33.1 | 43.2 | 40.9 | 52.3 | 50.3 | 62.7 | 61.5 | 74.4 |

| 500 | 12.3 | 19 | 15.3 | 23.4 | 19.1 | 28.9 | 23.9 | 35.700 | 29.7 | 43.8 | 36.800 | 53.3 | 45.4 | 64.5 | 55.8 | 77.3 | – | – |

| 560 | 13.7 | 23.6 | 17.2 | 29.4 | 21.4 | 36.2 | 26.7 | 44.7 | 33.200 | 54.8 | 41.2 | 66.900 | 50.8 | 80.8 | 62.5 | 97 | – | – |

| 630 | 15.4 | 29.9 | 19.3 | 37.1 | 24.1 | 45.9 | 30 | 56.5 | 37.4 | 69.400 | 46.3 | 84.6 | 57.2 | 102 | 70.3 | 125 | – | – |

| 710 | 17.4 | 38 | 21.8 | 47.2 | 27.2 | 58.4 | 33.9 | 72 | 42.1 | 88 | 52.2 | 107 | 64.5 | 130 | 79.3 | 160 | – | – |

| 800 | 19.6 | 48.1 | 24.5 | 59.7 | 30.6 | 73.9 | 38.1 | 91.2 | 47.4 | 112 | 58.8 | 136 | 72.600 | 166 | 89.3 | 202 | – | – |

| 900 | 22 | 60.9 | 27.6 | 75.6 | 34.4 | 93.4 | 42.9 | 115 | 53.3 | 141 | 66.100 | 173 | 81.7 | 210 | – | – | – | – |

| 1000 | 24.5 | 75.2 | 30.6 | 93.1 | 38.2 | 115 | 47.7 | 143 | 59.3 | 175 | 73.5 | 215 | 90.8 | 259 | – | – | – | – |

| 1200 | 29.4 | 108 | 36.7 | 134 | 45.9 | 166 | 57.2 | 205 | 71.100 | 262 | 88.2 | 304 | – | – | – | – | – | – |

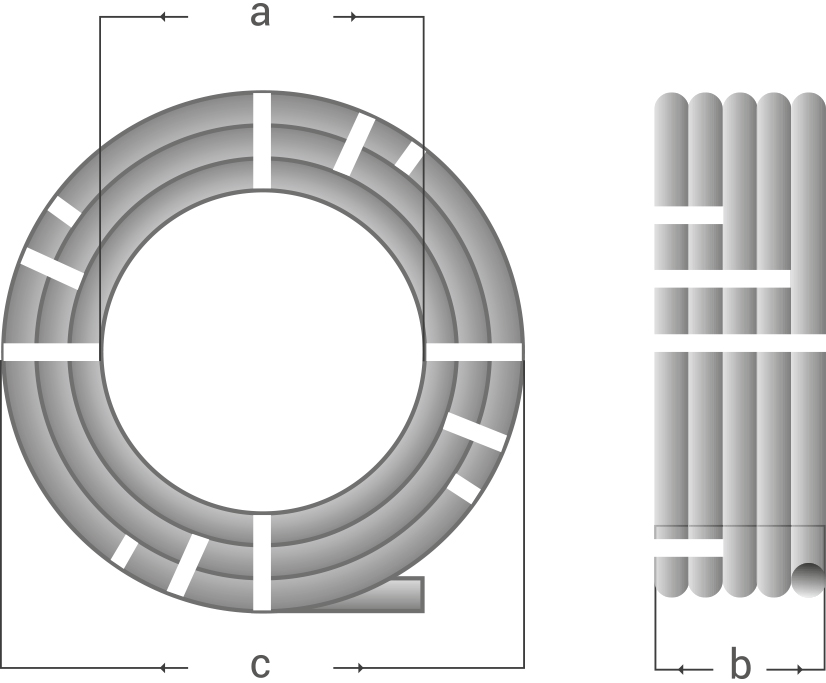

ESEN PE100 (HDPE) | Coil Dimensions and Lengths

* Diameters between ø20mm – ø125mm can be produced as coils.

| Diameter (DN) | Coil Inner Diameter (a)(cm) | Coil Width (b)(cm) | Coil Outer Diameter (c) (cm) | Coil Length (m) |

|---|---|---|---|---|

| 20 | 48+2 | 27+3 | 75±3 | 200 |

| 25 | 48+2 | 27+3 | 88±3 | 200 |

| 32 | 68+2 | 30+3 | 90±3 | 200 |

| 40 | 78+2 | 32+3 | 116±5 | 100 |

| 50 | 100+2 | 42+4 | 135±5 | 100 |

| 63 | 120+2 | 47+4 | 165±5 | 100 |

| 75 | 150+2 | 45+4 | 245±5 | 100 |

| 90 | 180+2 | 52+5 | 250±5 | 100 |

| 110 | 230+2 | 52+5 | 320±5 | 100 |

| 125 | 240+2 | 56+6 | 360±5 | 100 |

* Diameters between Ø63mm – ø1200mm can be produced in different lengths depending on request / project. Generally used lengths are 11,8mt and 13.5mt lenghts.

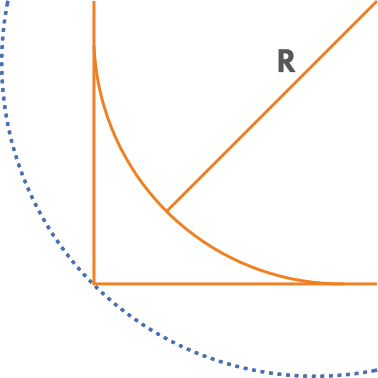

ESEN PE100 (HDPE) | Pipe Bending Calculation

Polyethylene pipes can be bent without using elbows at certain angles thanks to their flexible structures.

| SDR | MINIMUM BENDING ANGLE CALCULATION (20 °C ortam sıcaklığında) |

|---|---|

| 41,0 | >48 x Ø outer diameter |

| 33,0 | >40 x Ø outer diameter |

| 26,0 | >35 x Ø outer diameter |

| 21,0 | >28 x Ø outer diameter |

| 19,0 | >27 x Ø outer diameter |

| 11,0 | >25 x Ø outer diameter |

| 7,0 | >25 x Ø outer diameter |

EXAMPLE 1

for ø=400 ve SDR 33,

Ø400mm x 40 = 16000mm =16mt

EXAMPLE 2

for ø=400 ve SDR 11,

Ø400×25 = 10000mm =10 mt

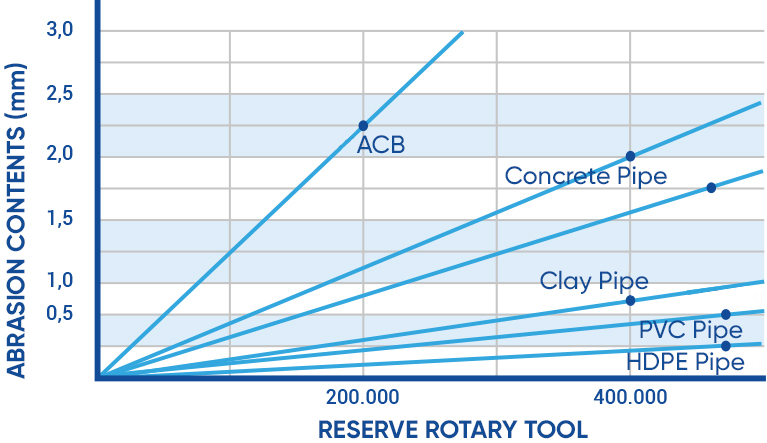

Test Results From Darmstadt Institute

Abrasion Test Results

Abrasion Resistance Test Results