Developed by Esen Plastik, Spiral Wound Corrugated Pipes are manufactured from high-density polyethylene (HDPE) using advanced extrusion and spiral winding technology. The outer surface of the pipes is produced in a spiral form to enhance ring stiffness, while the inner surface is designed to be smooth to ensure high flow capacity. They offer long service life, high chemical resistance, leak-tight performance, and easy installation—making them ideal for underground infrastructure systems.

Next-Generation Performance in HDPE Infrastructure Solutions

Nominal Diameter Range

Ø500 mm – Ø3600 mm

Superior Performance Features

✔ High Ring Stiffness

Thanks to its spiral-wound corrugated structure, it provides excellent resistance against underground loads. Tested in accordance with the TS EN ISO 9969 standard. Production is available in various stiffness classes from SN 4 to SN 16.

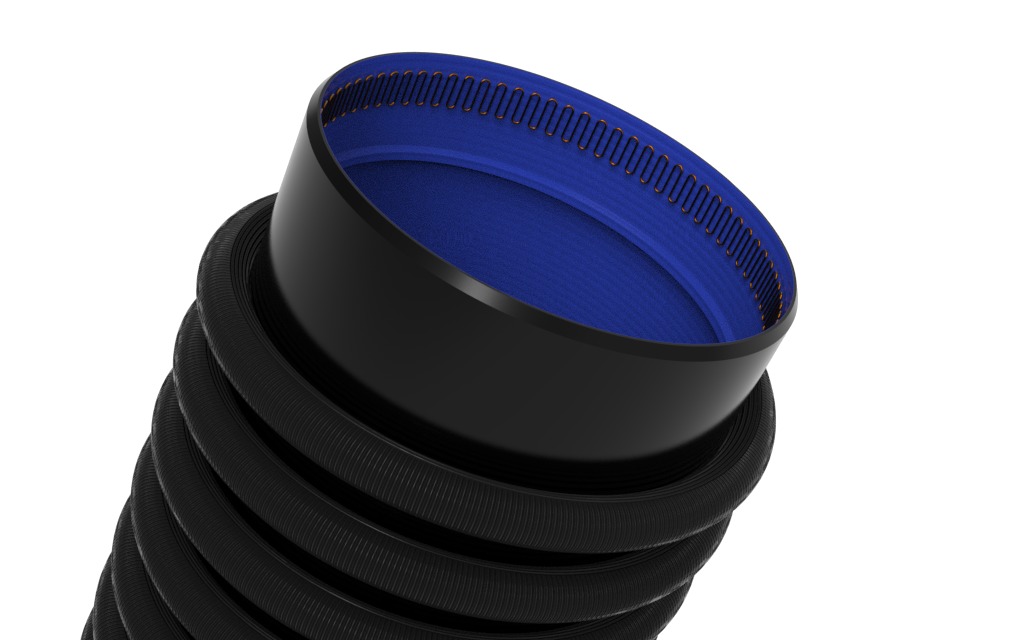

✔ Smooth Inner Surface – High Hydraulic Capacity

The low friction coefficient of the inner surface (k = 0.010 – 0.013 mm) allows for high-flow fluid transfer. Energy loss during fluid flow is minimized.

✔ Electrofusion Welding Technology

An integrated fusion wire located at the pipe ends enables electrofusion welding. This method ensures maximum leak-tightness while significantly reducing installation time. After welding, the system forms a unified monoblock structure.

✔ Chemical and Biological Resistance

HDPE material offers high resistance to acidic, alkaline, and many industrial chemicals. It does not corrode, rust, or support bacterial growth. It has successfully passed leak-tightness and chemical resistance tests in accordance with TS EN ISO 13259.

✔ Adaptability to Ground Movements

Thanks to the flexibility of polyethylene, the pipes do not crack or break during soil movements such as earthquakes, settlement, or shifting. In this respect, they offer a significant advantage over traditional concrete or PVC systems.

Applications

- Underground sewer systems

- Stormwater drainage lines

- Domestic and industrial wastewater conveyance lines

- Agricultural irrigation and drainage systems

- Urban infrastructure projects (urban and rural)

- Relining applications (insertion of new pipes into existing ones)

Advantages

- Low transportation and installation cost (lightweight structure)

- High mechanical strength and environmental stability

- Wide diameter range and custom production options

- Compliance with international standards

- Environmentally friendly and recyclable material