ESEN EasyFiber® has a wide product range from configuration 1Way up to 26+1Way Microduct, DN5mm to DN50mm Duct. The product range is consists of Microducts, Flat Duct, Flat Flex Duct, Duct, Indoor Microducts. ESEN has an accredited laboratory to perform all required tests on Microduct to achieve the best product quality. In this laboratory, ESEN can simulate conditions of actual practice in terrain and measure the behavior of our products when being installed. ESEN has a wide range and complete portfolio of product lines which is giving you excess options for your network design.

ESEN EasyFiber® Microducts are made only from virgin HDPE raw material and have a long service life. Microduct Products are the most appropriate for in-building infrastructure. All of these product lines can be customized to meet customers ‘ needs. Material, color, inner layer, diameter, and application; all give the customer a variation of products and the freedom to determine the most suitable solution.

APPLICATION

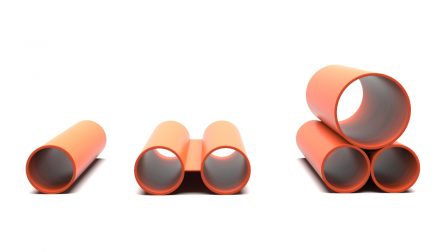

- Direct install

- Direct burial

MATERIALS

- HDPE

- LSHF

- UV Stabilized

- AntiRodent

- AntiStat

INNER LAYER

- Smooth Ribbed

- Silicone Layer

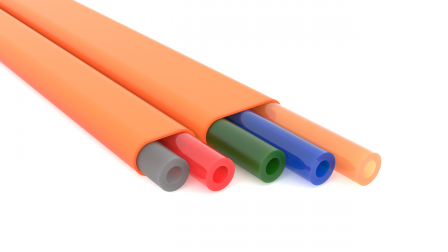

Microduct color codes

COLOR LIST

- Transparent

- Stripped

- RAL color codes

The bundle is supplied in natural translucent version or in a wide scale of the following RAL codes:

Microduct stripe color configuration can be customized as per customer requirements (i.e., Full colored, translucent, translucent with 3x pinstripes / 4x pinstripes).

Micro-duct inner layer can be customized as per customer requirements (i.e., Smooth, straight ribbed inner layer).

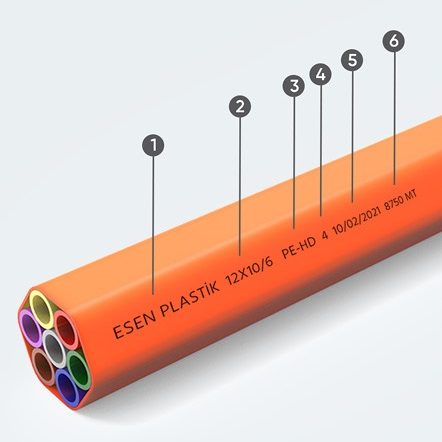

ESEN Easyfiber Microducts are marking with text according to the customer’s requirements. The color of the marking is in contrast to the Microduct color. The marking scheme is repeated every 1 meter along the Microduct unless otherwise specified.

ESEN has an accredited laboratory to perform all required tests on Microducts to achieve the best product quality, and it has proven the reliability of test results in our country and around the world.

All our production records are stored and available for customers or quality control.

ESEN Accredited Laboratory, equipped with modern technology products, qualified team of ESEN and the necessary equipment in accordance with international standards, conducts experiments and measurements on all relevant chemical and physical tests. In addition, it successfully performs the tests stipulated by the standards to determine the resistance of the ducts against adverse conditions that may affect the Microduct during installation.

One of the most significant features of Microduct, Inner clearance (Ball) test – steel ball with a specific diameter is blown into each duct to confirm that the inner diameter meets Specification. In this way, 100% reliability is ensured in our products.

Wounded Microducts on metal drums.

Microducts will be wounded on metal or wooden drums. All our products are packed, protected by stretched foil, and labeled with unified stickers.

Besides, as per customer request, the miniduct can be wounded in coils on a wooden pallet. Coils – Cost-effective for small-scale projects. Short coils allow machinery-free handling.

Standard Big Wooden or metal Drums (DB) – Heavy-duty duct packaging. Reusable. Several sizes are available to meet project requirements.